High efficient oilfree high pressure air compressor

for PET Blowing industry

Wide range of oilfree high pressure air compressor for various industries requirement in PET blowing, pharmaceutical,petrochemical and industrial gas

production, etc., are also increaseingly customer demand,Kunshan Compairs Machinery Plant Co.,Ltd. Specialized in the development of oilfree high

pressure air compressor,produce better cost effective with superior performance and lower power consumption.The company registered national patnets right.

China and worldwide, we have appointed agents in Malaysia,Singapore,Thailand,Philippine, Indonesia, South africa,north american,australia with qualify

prefessional engineers to provide customer technical training,assistant and after sales service support.

Shanghai Souair Industrial co.,Ltd. Can be customize the most reliable oilfree high pressure air compressor to suited oil and gas,

medical,food and beverages industries.

1) 36-264 M3/hr PET Oil Free Piston Air Compressor

1, oil lubrication, no oil compression, bring a high quality high stable no hydraulic pressure compressor

2, cast iron structure: cylinder and 100% of cast iron material used crankcase, ensure the life of unit.

3, cylinder: deep, independent of the fin casting cylinder 360 degrees can remove the heat generated by compressed air. Cylinder

with the crankcase with bolt connection between, convenient for daily maintenance and maintenance.

4, flywheel: the flywheel leaves to produce a "whirlwind" type air to cooling deep fin cylinder, inter-coolers and after cooler.

5, inter-coolers: finned tube type, installed directly in the flywheel blowing place.

6, after cooler: finned tube type, the air-filled type, and inter-coolers as installed

in the flywheel blowing place. The discharge of compressed air cooler than about 20 ℃ high temperature environment to the left

7, centrifugal unloading device: release from the cold and cylinder air, prevent the overload start.

8, adjusting device: all of the high pressure units configure automatic start/stop control, another can choose constant speed

control and dual control.

9, automatic condensing emission system: automatic condensing drain valve installed in the exhaust valve holder/separator,

when compressor stop or in constant speed control mode uninstall automatically, and condensed water discharge.

10, motor: TEFC, motor, accord with IP54 IEC standard.

11, the driver: fully enclosed the protective bubble "V" type driving belt, smooth operation.

12, base: on the base of the structure of the chongqing opened a small chamfer, motor can be moved, easy to tighten "V" type belt.

PET Compressor-Technical Data Sheet

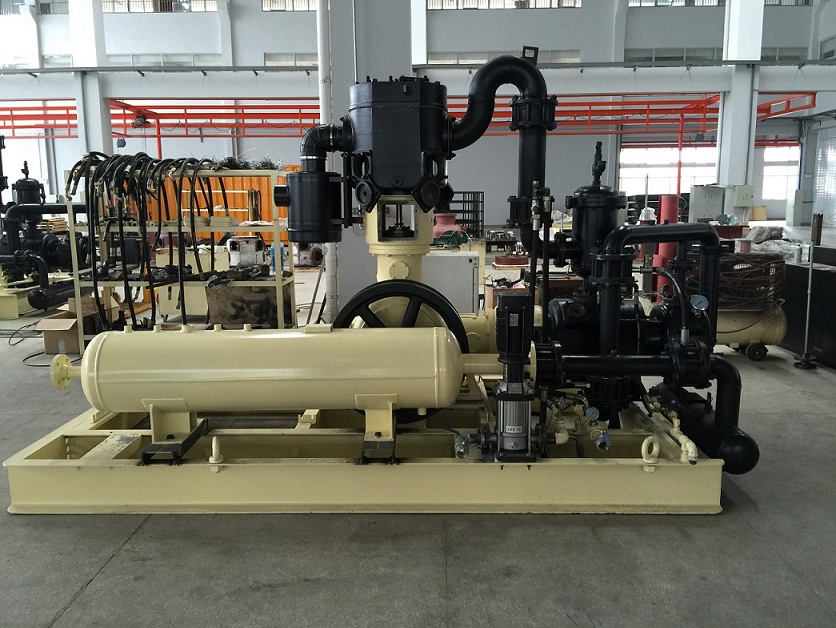

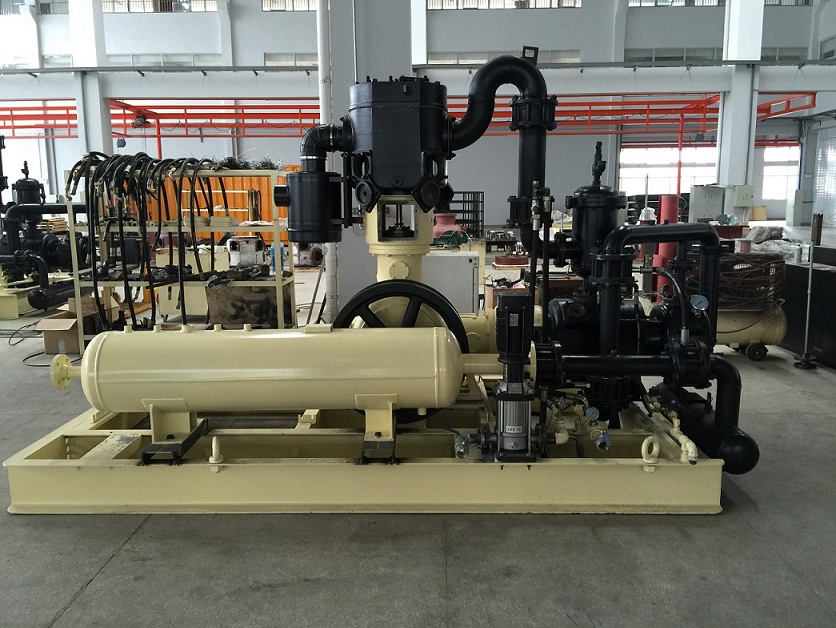

2) 510-1320 M3/hr PET Oil-Free Piston Air Compressor

Environmental friendly air compressors with higher efficiency at lower cost

Products main advantages:

Lowest speed oil free high pressure air compressor

The oil-free high pressure air compressor core parts polytertrafluoroethylene(PTFE) piston rings has been proven reliable in PET industry with 24hours

continuous operations. Compairs company experienced technical team,design engineering focus on low speed,low piston load with specific operating

temperature to optimism piston rings life span and other moving components.

1.Low speed: From 355- 466 rpm

2.Piston stroke: 10-30% more as compare with similar industry

3.Piston load: long stroke and small piston diameter,reduce pistons load

4.Discharge temperature between 90-130 C degree,greatly extend the life span of the discharge valves ,packing seal,piston rings and other wearing parts

5.Increased the number of piston rings: each level and more with 1-3 rings,reduced compression lost of each stage,increased air delivery

6.Low vibration: precise well balance machined components to achieved dynamic balance and reduces vibration

7.Isobaric Ratio: precise compression design,with equal pressure ratio at each individual stage to improve volumetric efficiency ,reduce energy

consumption significantly

8.Compression stage: three stage design,with double-acting cylinder on first stage,and single-acting cylinders on second and third stage

9.Each stage has a high efficiency chiller,the compression cycle neraly isothermal compression,reducing the power loss

Easier to use and more simple maintenance

Perfect system configuration

The machine adopts”L” shaped design, long stroke,simple structure,host components mounted on a rack,to over come the “V” and “W” type of stoke is shorter

and more complex structure shorcomings. Minimal moving parts, the second and third stage is small, and the horizontal placement, the maximum extension

of the life of the piston ring.

1.Low installation cost without special foundation for fast,simple and easy maintenance. Skid mounted V-Belt driven complete with main components,

lubrication, cooling water,and compressed air system.

2.Control panel: Real time operation perimeter LCD display with integrated PLC control monitoring individual stage discharge temperature and pressure,

oil lubricating and cooling water pressure, safety fault alarm and trip protection with data logging for easy trouble shooting and maintenance.

With optional automatic duty/stadby cycle sequence coontrol for multi units and centralize computer monitoring.

3.Safety: Double safety protection, built-in safety valves and pressure sensors at each individual stage, an additional

discharge high pressure switch protection.

4.Oil cooler and direct couple oil lubrication pump, optional crankcase oil heater configure to customer requirement

5.Booster water pump, to ensure sufficient pressure /flow to water-cool system. Water-cooled intercooler and after-cooler at each stage,integrated with automatic timer condensate drain.

Optional energy-saving equipment

1.Drive: by installing the drive on the compressor, the compressor effectively eliminate or reduce working hours in the unloaded state

(Unloaded state will consume energy,not to produce compressed air),designed so that the host is in the low rpm operation, reducing power

consumption up to 30-50%.

2.Blowing gas recovery: If you want to waste gas compressor air blowing machine produced 0.5-1.4 MPa in for recycling, we can design a special device,compressed air sent to this parts of second or third level, increase it as press,

pressure 4.0Mpa or blowing pressure you need to make both the highpressure oil free booster function. After modification 1 M3/min of compressed

air energy saving 4.4-5.6kw, once converted into a large.

Technical Parameters:

|

Pacakge model

|

Bare model

|

Delivery FAD

(M3/min)

|

Pressure

(MPa)

|

Speed

(r/min)

|

Power

(Kw)

|

|

61HLW-8.5/40

|

HW08A

|

8.5

|

4.0

|

460

|

90

|

|

61HLW-10/40

|

HW08A

|

10

|

4.0

|

550

|

110

|

|

58HLW-10/40

|

HW12B

|

10

|

4.0

|

355

|

110

|

|

58HLW-12.5/40

|

HW12B

|

12.5

|

4.0

|

450

|

132

|

|

58HLW-15/40

|

HW12B

|

15

|

4.0

|

520

|

160

|

|

60HLW-18/40

|

HW22B

|

18

|

4.0

|

375

|

200

|

|

60HLW-22/40

|

HW22B

|

22

|

4.0

|

455

|

250

|

Important options

The unit uses a water-cooled water temperature is required, to be provided with water cooling system

Evaporative cooling towers

Cooled heat pumps,automatic spray system,the envoironment for up to 32 C degree

Other options

4.0MPa refrigerated air dryer(water/air cool),dew point alarm,integrated early filtration system(Option)

4.0 MPa Tank (China national standard GB150, ASME or stainless steel tank(Optional)

Oil heater(optional)

4.0 MPa check valve (Optional)

IP55 motor (optional)

English

English  中文

中文  Español

Español  Русский

Русский