Atlas Copco Surface drill rigs

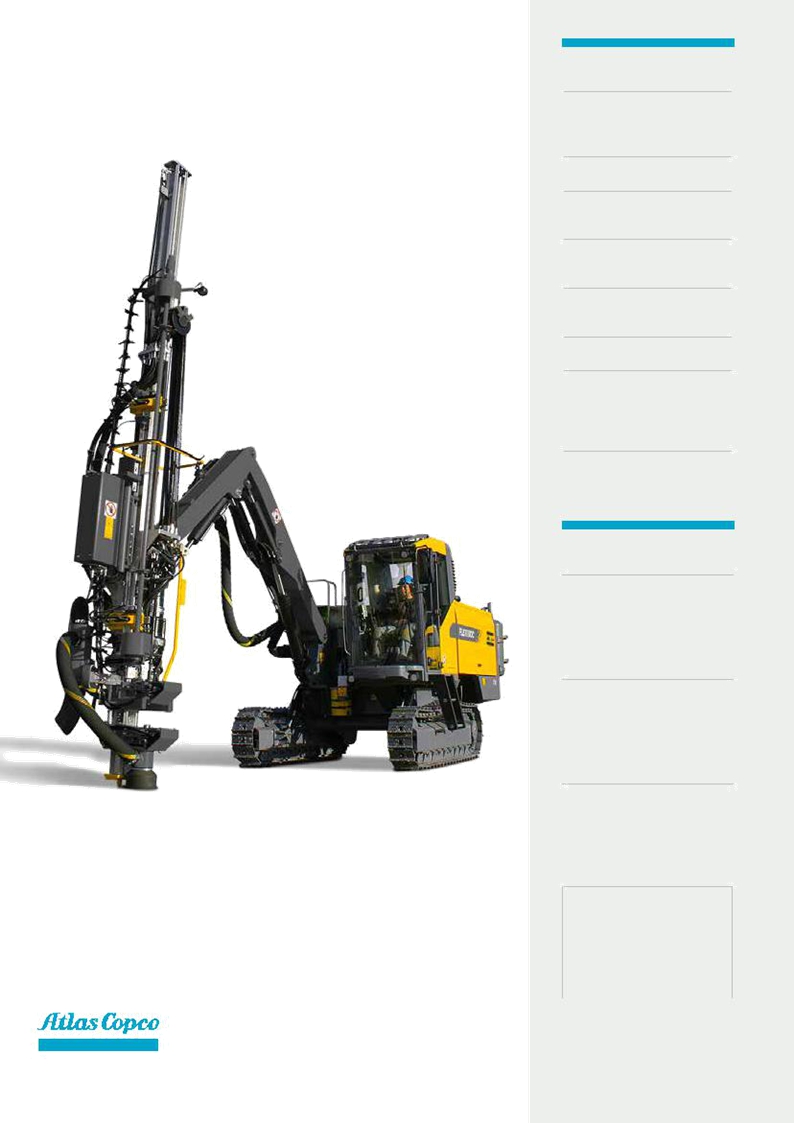

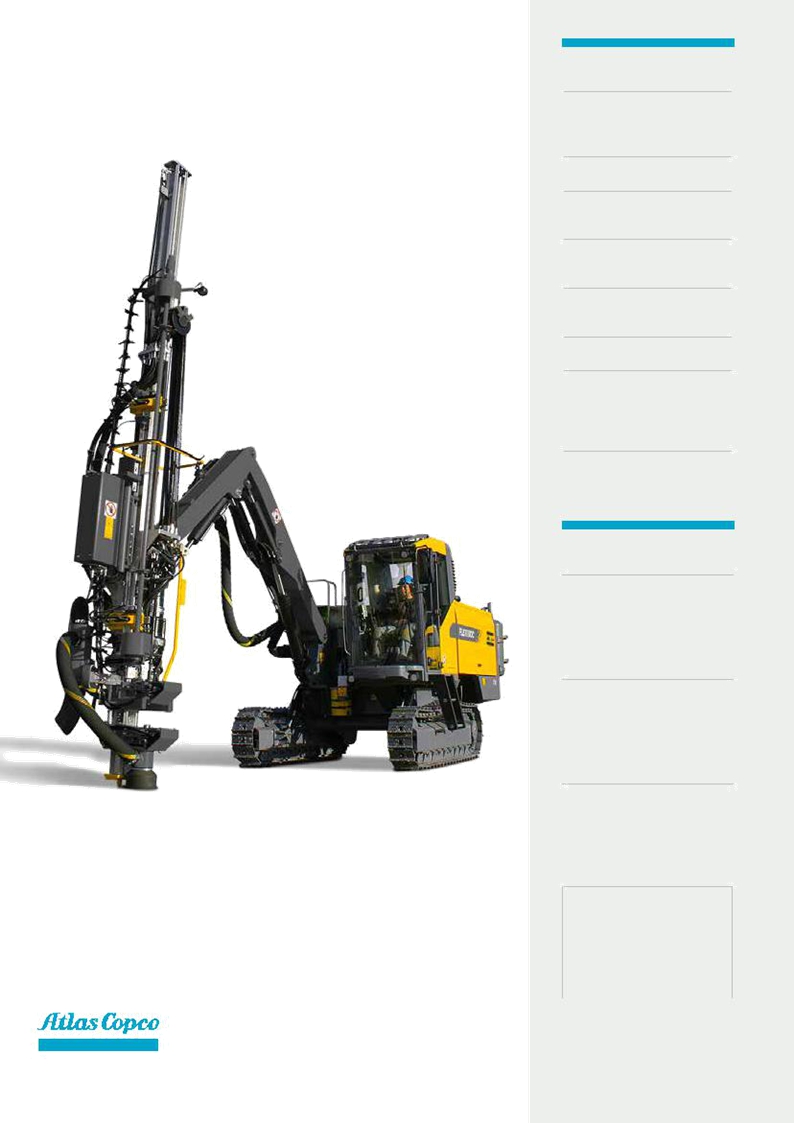

FlexiROC T35 and T40

Hole diameter

FlexiROC T35, 64–115 mm (2 1/2’’ – 4 1/2’’)

FlexiROC T40, 76–115 mm (3”– 4 1/2”)

Flexible rigs for all occasions

For efficiency and flexible production; Atlas Copco’s FlexiROC T35 and FlexiROC T40 surface drill rigs are hard to beat in the quarry or on the construction site.

Rock solid rigs

FlexiROC T35 and FlexiROC T40 are flexible and versatile tophammer drill rigs, developed and designed for high performance in demanding construction

applications. They are also a very efficient alternative for small and medium size quarrying jobs. Even in tough terrain conditions, utilization of

the rig is high, thanks to the long reach of the boom, the low center of gravity and hydraulic support leg that can be used during tramming. It is

equipped with a high-efficiency Atlas Copco rock drill with high output and productivity.

Cost efficient penetration

A floating double damping system on the rock drill means positive rock bit contact for great penetration and low consumable usage. You’ll drill fast and

deep with good overall economy. You’ll get perfect collaring and stable drilling thanks to the powerful and rigid boom design.

Operator comfort improves productivity

The ROPS and FOPS approved cabins provide both comfort and safety. Reliable and fast rod handling makes work go fast and smooth and a rigid drill

steel support decreases hole deviation for more accurate and higher quality holes. Maintenance is convenient as well, thanks to an efficient design.

When there’s work to be done, your FlexiROC T35 and FlexiROC T40 will deliver.Tough and dependable, these rigs are built Atlas Copco solid. Thanks to a high

degree of commonality with other Atlas Copco surface drill rigs and a worldwide service network, spare parts and consumables are there when you need

them to insure continuous uptime and great performance.

Main benefits

•Optimal use of rock drill and increased tool life thanks to a cylinder-oper-ated feed system

•Long boom reach is ideal for demanding construc-tion jobs

•Supreme productivity thanks to proven COP rock drill series

The use of the rock drill with its unique double dampening system improves productivity and drilling economy.

01.The cabin is ROPS and FOPS approved and has a protective plate under the cabin. A reinforced front window is also available for the highest level of

safety.

02.Hydraulic cylinder feed system with rigid aluminum feed beam for precise feed force and long drill steel life.

03.Designed to meet the latest emissions regulations with Tier 3/Tier 4 engines.

Technical Specification

Main application:Limestone quarries/Aggregate quarries/Construction

Drilling method: Tophammer

Tophammer

FlexiROC T35: COP 1840

FlexiROC T40: COP 2560

Drill steel

FlexiROC T35: T38, T45, T51

FlexiROC T40: T45, T51

Hole diameter

FlexiROC T35: 64-115 mm (2 1/2” – 4 1/2”)

FlexiROC T40: 76-115 mm (3”– 4 1/2”)

Maximum hole depth: 28 m (92')

Engine power

Tier III Rating at 2200 rpm 168 kW (225 HP)

Tier IV Rating at 2200 rpm 168 kW (225 HP)

Available air flow (FAD)

FlexiROC T35: 127 l/s (270 cfm)

FlexiROC T40: 149 l/s (316 cfm)

Selection of options

Stabilize the hole walls

The water mist system is a perfect option for stabilizing the hole wall when drilling in poor rock formation. It consists of a 120 liter (32 US Gal)

pressurized water tank connected directly to the flushing air.

Straight inclined holes

The hole inclination and hole depth instrument, located inside the cabin, assures drilling straight, inclined holes and fast feed positioning. The

instrument also increases safety and reduces production costs.

Extra support

The robust, hydraulically positioned support leg is used for stable set up when drilling. It can also be used to stabilize the rig when moving in rough

terrain.

English

English  中文

中文  Español

Español  Русский

Русский