ROC D7 Hole Diameter:64-115mm(21/2″-41/2″)

The true companion for a wide range of applications

Sustainable Productivity

Tough on rock

Friendly to environment

In better shape than ever

Since the first D-series rig was delivered in late 1999, its popularity has been impressive, and well above 1000 rigs have been delivered to satisfied customers all around the world. But that doesn′t mean we are satisfied. Atlas Copco is continuously making improvements in order to raise your productivity to the sky. Today′s ROC D7 is better than ever. And by introducing ROC D9 with more powerful rockdrill and improved flushing the next step in productivity is taken.

The bestsellers

High productivity thanks to the use of Atlas Copco supreme rockdrills, covering a wide hole range

Perfect collaring and stable drilling thanks to the strong and stiff boom design.

Durable cylinder-operated aluminium feed system for optimal penetration rate and drill steel life

Ideal for use in slope stabilization thanks to its long boom reach.

The use of the rock drill with its unique double dampening system improves productivity and drilling economy.

Hydraulic cylinder feed system with a rigid aluminium feed beam with precise feed force for longer drill steel life.

The cabin is ROPS and FOPS approved and with a protective plate under the cabin. You can also add a reinforced front

window to achieve the highest level of safety.

Environmental productivity

The ROC D5, D7 and D9 rigs are equipped with CAT stage3/TierIII engines which meets all the new exhaust emission limits. The rigs will deliver exactly the power you need in each phase of the operation, which considerably reduces the fuel consumption. The rigs also come with a big fuel tank which secures 12 hours of continous operation and secured start-up through the powerful generator and batteries.

Great balance and stability

The track frames have an optimal position for taking you safely wherever you want to go. The rigs are equipped with a strong and stiff boom for precise collaring and stable drilling of quality holes.

Siberia or Sahara?

High visibility, space, quietness, quality! That’s what you get with our cabin layout. The high capacity air condition and heating system gives excellent comfort for the operator, whether you operate in Siberia or the Sahara.

Save time with Long Feed

ROC D7 is available in a LF (Long Feed) version handling 6.1 m (20 ft) starter rod and one 4,3 m (14 ft) rod in the RAS (Rod Adding System). A perfect choice for saving time by eliminating the changing of rods when drilling holes are shorter than 6 m (20 ft).

A selection of options on ROC D7 and ROC D9

For a more comprehensive list, please contact your local Atlas Copco Customer Center, or look in the technical specificatio

Stabilize the hole walls

The water mist system is a perfect tool to stabilize the hole walls when drilling in bad rock formation. It consists of a 120 litres (32 US Gal) pressurized water tank connected directly to the flushing air.

Straight inclined holes

The hole inclination and hole depth instrument, located inside the cabin, assures the drilling of straight, inclined holes an feed positioning. The instrument also increases safety and reduces the production cost.

Extra support

The robust ,hydraulically positioned support leg is used for stable set up when drilling. It can also be used to stabilize the rig when moving in rough terrain.

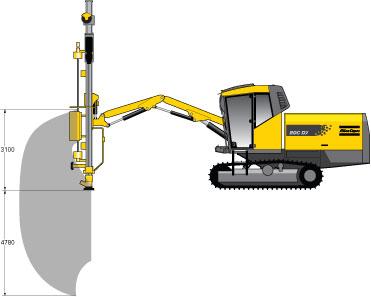

Designed both for construction and quarrying work, andbased on extensive research at work sites throughoutthe world, the ROC D7 with cabin is a crawlerdrill with true 102 mm tophammer capability, for benchheights up to 28 m. A fuel efficient diesel engine deliversthe power needed for quick penetration and efficientflushing.

Main benefits

· Unique, durable cylinder-operated feed system makes the best use of the rock drill

· Long reach makes it ideal for use in slope stabilization

· Supreme productivity thanks to the use of the proven COP-series of rock drills

Technical specification

|

Recommended hole range

|

|

T38, T45, T51

|

64-115 mm

|

2 1/2''- 4 1/2''

|

|

Hole depth

|

28 m

|

approx. 92'

|

|

Hydraulic rock drill

|

|

COP 1840, COP 1840EX

|

|

Impact power, max.

|

18 kW

|

24.5 hp

|

|

Atlas Copco OIS K-27-C106 GD, screw compressor

|

|

Working pressure, max.

|

10.5 bar

|

152 psi

|

|

FAD

|

105/127 l/s

|

223/270 cfm

|

|

Engine

|

|

Caterpillar turbo charged, diesel engine, CAT C7, Tier III/stage 3

|

|

Rating at 2200 rpm

|

168 kW

|

225 hp

|

|

Boom variants

|

|

Folding boom system

|

|

Fuel tank

|

|

Capacity

|

370 l

|

98 US gal

|

|

Feed

|

|

Feed length, total

|

7,140 mm

|

23'5''

|

|

Travel length

|

4,240 mm

|

14'

|

|

Feed extention

|

1,400 mm

|

4'3''

|

|

Feed force, max.

|

20 kN

|

4,400 lbf

|

|

Tramming

|

|

Traction force, max.

|

142 kN

|

31,920 lbf

|

|

Track oscillation

|

±12º

|

|

|

Ground clearance

|

455 mm

|

17 1/2''

|

|

Transport dimensions

|

|

Total weight, approx.

|

14,500 kg

|

32,000 lb

|

|

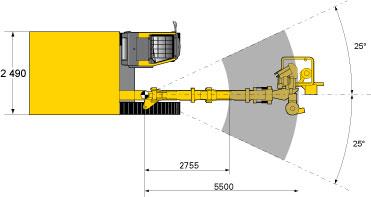

Width

|

2,490 mm

|

8'2''

|

|

Length feed dumped

(back/forward)

|

11,000 mm/10,900 mm

|

36'/35'9''

|

|

Height feed dumped

(back/forward)

|

3,200 mm/3,500 mm

|

10'2''/11'6''

|

Noise and vibration levels

|

ROC D7

|

|

A-weighted sound power level in decibel (ref. 1pW)

Single value declaration

|

127

|

|

A-weighted sound pressure level at work station in decibel (ref. 20 mPa)

Double value declaration

|

78

|

|

Accurancy, KpA, in decibel

|

3

|

|

A-weighted sound pressure level at 1m distance in decibel (ref. 20 mPa)

Double value declaration

|

NA

|

|

Accurancy, KpA, in decibel

|

NA

|

|

Weighted whole body vibration level (m/s2) (Double value declaration)

|

0.2

|

|

Inaccuracy (m/s2)

|

0.1

|

Standard

Satisfy the anti-ROS defense roll and FOPS cab air-conditioning requirements rockfall

Rod wrapping device

Dual Hydraulic Rotary drill device

Foot hole drilling device

Two-speed motor running

Dust catcher

Pre-separator

Automatic anti-card technology

Vacuum switchgear

Air flow control switch

Mechanical point of instrument

Brush oil drill pipe thread lubricating device

Portable catching dust cover

Heavy tracked chassis

Working headlights

Optional

Drill pipe thread lubricant spray device (ECG)

Hydraulic winch

Connected sets holder

Engine Preheater

Centralized lubrication system

Electronic angle meter

Electronic angle meter deep hole

Slag water mist system

Anti-playing device rock drill

Cab seat heaters

Sun visor

After the hydraulic legs

Electric pumps

Coverage area

English

English  中文

中文  Español

Español  Русский

Русский