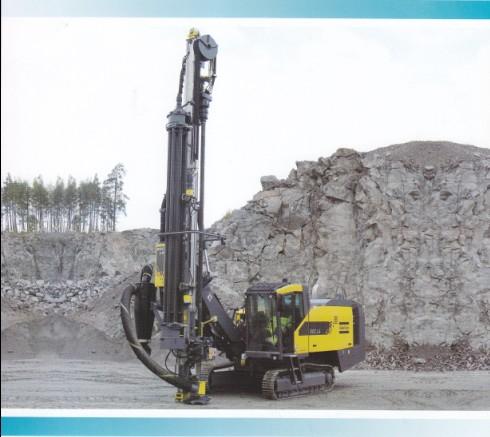

ROC L625& ROC L630

Master of quarry blast hole drilling

Hole diameter 92mm-152mm

Power and productivity

ROC L625& ROC L630are high-capacity down-the-hole crawler drills primarily designed for quarry blast hole drilling in virtually all types of rock formations for aggregate production and limestone for cement production. Fitted with Atlas Copco’s high pressure compressors, 25 and 30 bar, and powerful CAT C11 and C13 diesel engines the ROC L6 series is also appreciated in mining operations and coal over- burden drilling thanks to its flexibility and overall drilling capacity and economy.

Flexibility, precision and mobility

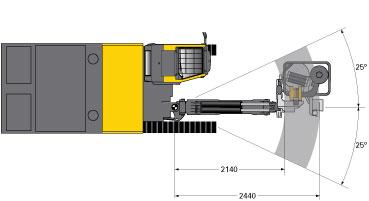

The ability to drill in different angles and to accurately set the hole inclination and control the depth of the hole contributes to the overall economy of the operation. The boom and feed movements of ROC L6 offers excellent flexibility for vertical, horizontal and angle drilling. A well balanced design and limited transport dimensions makes the rig movement smooth and transport from site to site easy.

The ROC L6 gives you:

Efficient utilisation of hammer capacity through a unique cylinder feed system Productivity beyond conventional rigs using down-the-hole hammers Transport configuration ideal for single or multi site operations Straight accurate blast holes for controlled fragmentatoin Deep hole drilling capacity Flexible drilling angles

Long life aluminium box profile hydraulic cylinder feed system with exchangeable snap on stainless steel wear protections

Carousel tube handling system with deep hole capacity

A selection of rotary heads for optimum use of 3–5" down-the-hole hammers

Full view ROPS and FOPS cabin, silenced and vibration damped

Full-length, spring operated canopy doors offers full access to service points

Flexibility and mobility in focus

The ROC L6 has excellent tramming ability for quick, safe transportation on site and between work sites. The ROC L6 features a strong single section boom design that permits the operator to position the feed for transport or drilling, precise and fast, from within the cab.

DTH hammers – strikingly efficient

The ROC L6 series can be equipped with a range of Atlas Copco down-the-hole (DTH) hammers well known for their high performance in terms of speed, reliability and longevity. With higher penetration rates and lower fuel consumption per meter drilled Atlas Copco's hammers make a positive impact on your bottom line.

Designed to keep you up and running

Like all our crawlers, the ROC L6 is designed for easy maintenance with ready access to service points. All hoses and cables are marked at each end to coincide with the schematic drawings in spare parts lists for easy trouble-shooting.

Drilling made perfect

The electronic hole inclination and depth control instrument combined with a laser receiver (optional) ensure that all blast holes are perfectly aligned and drilled to a predetermined level irrespective of the ground conditions. With the optional GPS compass all holes are guaranteed in parallel towards the blasting direction. Mentioned features ensure even bench bottoms, controlled fragmentation, easier loading and haulage and savings in the total excavation cost.

The optimum rig for multi site operations

Focus on the rig

The ROC CARE package is designed for contractors and quarries at their surface drilling operations.The package includes scheduled maintenance,rig inspections,extended warranty for all major rig components and procom.

Lifting aid

The feed mounted service which offers lifting capacity when loading drill tubes into the rod handling system for extend hole depth,or for lifting of components at service.the control is conveniently located at the break out table.

Fast and accurate

The GPS Compass aiming device uses the GPS satellite system and enables you to lock the blast direction for every hole in the blast.GPS compass adds a new dimension to the extensive automation already available on ROCl6

Increased safety

With the back camera the rear terrain can be viewed on a cab mounted monitor for increased safety at rear tramming.the same monitor may also be connected to the optional DVD for viewing DVD discs.

Technical specification

|

Recommended hole range ROC L625

|

|

COP 34, COP 44

|

95-130 mm

|

3 5/8''-5 1/8''

|

|

|

Recommended hole range ROC L630

|

|

|

COP 34, COP 44, COP 54, COP 54GE

|

110-152 mm

|

4 1/3''-5 1/8''

|

|

|

Hole depth

|

45 m

|

148'

|

|

|

Atlas Copco XRX 10, two stage screw type compressor

|

|

|

ROC L625

|

|

|

Working pressure, max.

|

25 bar

|

363 psi

|

|

|

FAD

|

295 l/s

|

625 cfm

|

|

|

ROC L630

|

|

|

Working pressure, max.

|

30 bar

|

435 psi

|

|

|

FAD

|

354 l/s

|

729 cfm

|

|

|

Engine

|

|

|

ROC L625

|

|

|

Caterpillar turbo charged, diesel engine, CAT C11, Tier lll/Stage 3

|

|

|

Rating at 1,800 rpm

|

287 kW

|

440 hp

|

|

|

ROC L630

|

|

|

Caterpillar turbo charged, diesel engine, CAT C13, Tier lll/Stage 3

|

|

|

Rating at 1,800 rpm

|

328 kW

|

440 hp

|

|

|

Fuel tank

|

|

|

Capacity

|

760 l

|

201 US gal.

|

|

|

Feed

|

|

|

Feed length, total

|

11,560 mm

|

38'

|

|

|

Travel length

|

5,400 mm

|

17'7''

|

|

|

Feed extention

|

1,900 mm

|

6'3''

|

|

|

Feed rate max.

|

0.9 m/s

|

177 ft/min

|

|

|

Feed force, max.

|

40 kN

|

8,992 lbf

|

|

|

Tramming

|

|

|

Tramming speed, max.

|

3.5 km/h

|

2.2 mph

|

|

|

Traction force

|

166 kN

|

37,310 lbf

|

|

|

Track oscillation

|

+10º

|

|

|

|

Ground clearance

|

405 mm

|

16''

|

|

|

Transport dimensions

|

|

|

Weight, excl. options

|

21,700 kg

|

47,900 lb

|

|

|

Length

|

10,700 mm

|

35'1''

|

|

|

Height

|

3,200 mm

|

10'6''

|

|

Standard

* Three teeth with heavy track frame track shoes

* Track frame swing unit and two-speed hydraulic motors running

• Start spring control chassis protective door

* For 50 ℃ ambient temperature of the hydraulic cooling system

* Hydraulic oil filter with manual pumps

* Cooling fan speed control system - to save fuel

* Engine speed control system - to save fuel

* Air traffic control, automatic anti-shock and decompression card system

* Meet the requirements of ROPS and FOPS cab air-conditioning

* Adjustable cab seats six

* Engine condition and angle of hole depth color display

* Cab stairs

* The front window and top window wiper

* Cab platform with the former also offering a toolbox out of the window

* Covered with stainless steel wear-resistant aluminum alloy cylinder propulsion guideway beam

Dual Rotary drill capture devices and removable dust cover

* Hydraulic unloading rod table

Automatic system for bar

* Foot hole device

Optional components

* Hydraulic rear outriggers

* Hand-held work light chassis

* Reversing warning light and buzzer

* For 55 ℃ ambient temperature of the cooling fan

* Electric fuel pumps

* And below 25 ℃ for cold temperature installations

* Cab heating system

* Right side of the window wiper

* Jet thread lubrication device

* Slag Pump-type water spray systems, water tanks containing 400l

• Suitable for cold climate, water pump-type spray blowing slag system, including tank 400l

Noise and vibration levels

|

ROC L6(25) / L6(30)

|

|

A-weighted sound power level in decibel (ref. 1pW)

Single value declaration

|

127

|

|

A-weighted sound pressure level at work station in decibel (ref. 20 mPa)

Double value declaration

|

80

|

|

Accurancy, KpA, in decibel

|

3

|

|

A-weighted sound pressure level at 1m distance in decibel (ref. 20 mPa)

Double value declaration

|

NA

|

|

Accurancy, KpA, in decibel

|

NA

|

|

Weighted whole body vibration level (m/s2) (Double value declaration)

|

0.3

|

|

Inaccuracy (m/s2)

|

0.2

|

Coverage area

The Hole World - ROC L-series

English

English  中文

中文  Español

Español  Русский

Русский