Pet screw air compressor 17bar25bar30bar35bar40bar for Bottle making machine.

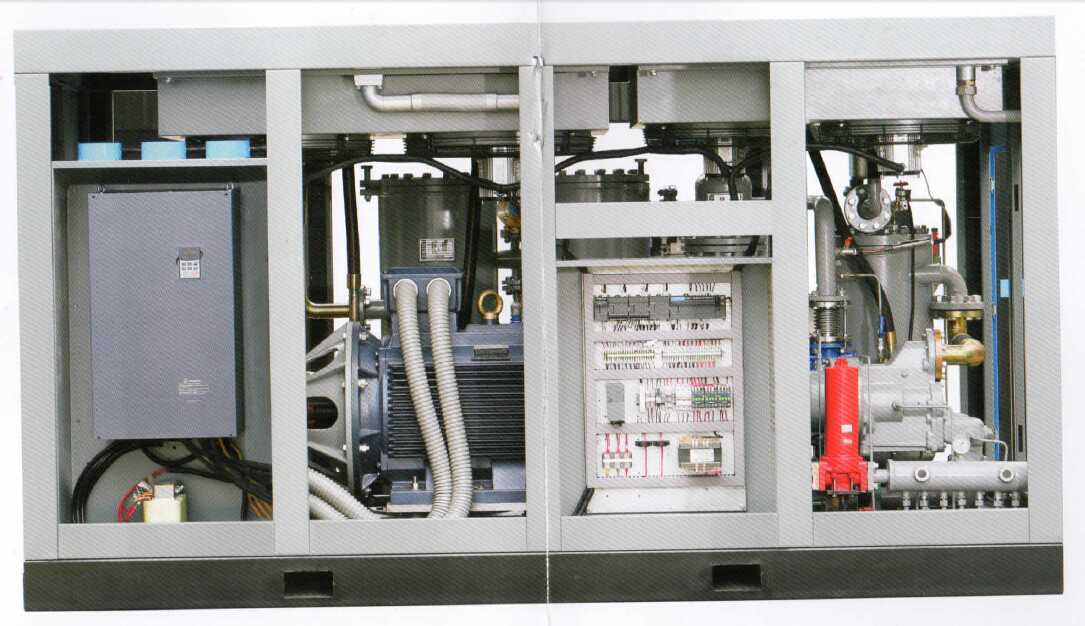

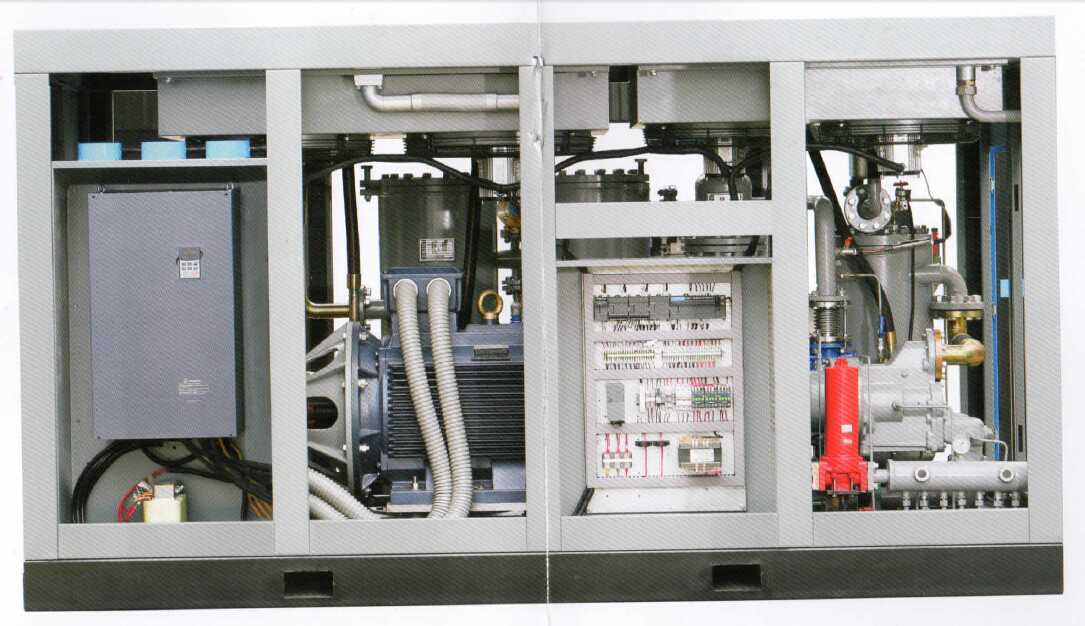

Characteristics of every part

1)one/two stage screw air end

Choose a one or two stage air end. The two stage air end’s structure features one screw above the other, separately completing compression via gear transit. The one stage reaches up to 4bar and two stage up to 13bar, with the entire compression process coming close to isothermal compression. The two stage air end features a very high insulation efficiency,hence decreasing energy consumption,which can save 10%-15% more energy than a single stage compressor.

2)Three stage compressor air end

Advanced technology adopted from germany with especially meticulous design for a medium pressure compressor. The rotors feature a small draw ratio,configured with heavy-duty imported bearings. This ,along with low speed and low noise,can ensure long and reliable operation,even under poor working conditions. Frequent maintenance is unnecessary.the pressure of a three stage compressor can reach up to 40bar.

3)Main motor

A special double-shafted motor designed especially for screw compressors,equipped with protection class IP54 SKF bearings and F Class insulation. This motor ensures uninterrupted and effective running with high energy savings.

4)Cooling system

The efficient cooling system is divided into primary/secondary stage and third cooling,which are separately controlled and do not influence one another. Each stage achieves a low discharge temperature(only 5-15℃ higher than ambient temperature)

5)Oil-Air separator

The excellent design of the oil-air separation process, as well as the great characteristics of the separator,produce lower exhaust oil content(<3ppm)

6)air-liquid separator

The unique and efficient oil-water separation technology,patented by Baosi,makes the lubricating oil much cleaner and longer serviceable.This ensures the long-term reliability of the unit during three-stage compression. The dew point of the compressed air is <5℃

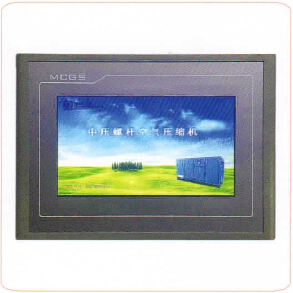

7)LCD Touch screen

The LCD touch screen is designed to clearly and directly reflect all parameters of the unit,as well as to allow for simple and quick modification of these parameters.

8)control system

A Siemens PLC integrated control is used,which takes samples with temperature and pressure sensor to fully detect and control the motion of the compressor automatically. It can effectively control the use of energy and ensure the long and efficient operation of the compressor.

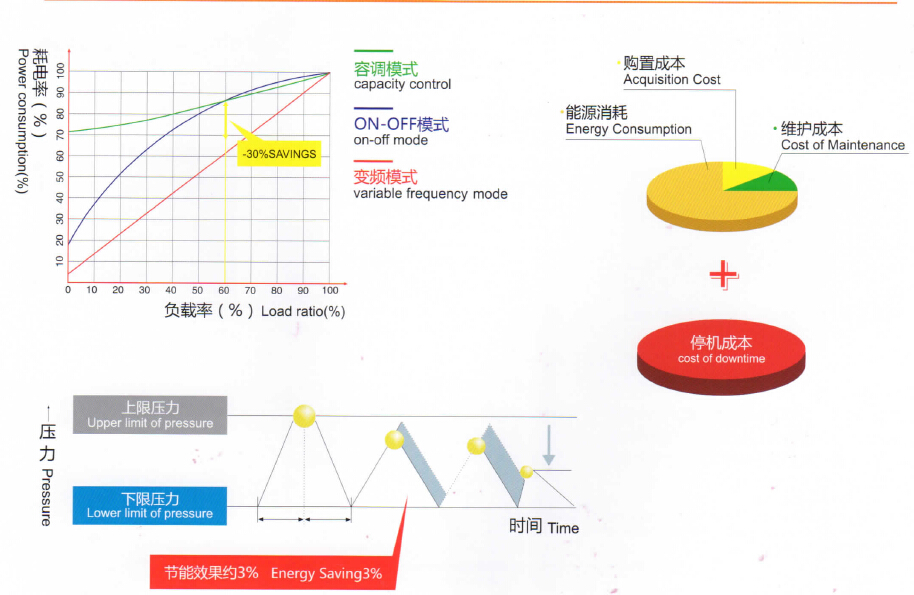

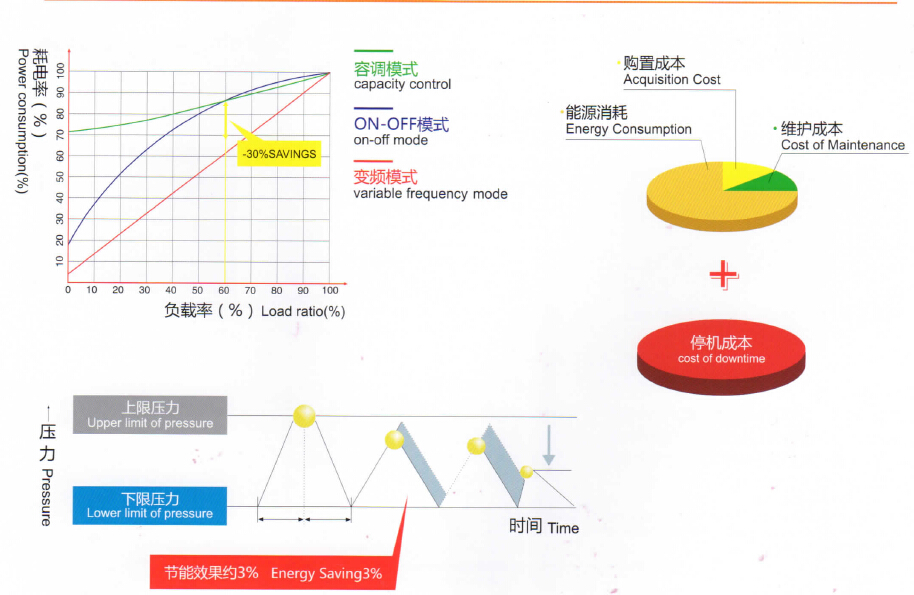

9)Frequency converter

A special BAOSI frequency converter is perfectly integrated into the unit. This converter momentarily decreases the electrical current supplied during startup to protect the electricity network. Revolution speed can be adjusted by changing the frequency according to the usage of air,this makes the unit more energy efficient.

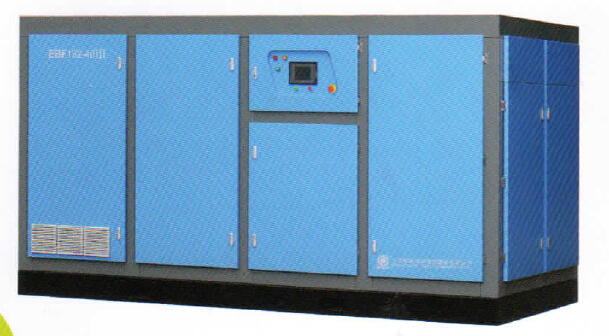

10)overall appearance

Clean and beautifully colored cover paneling reduces internal dust,help to provide quiet operation,and protects the environment.

| Parameters of 17-25bar series two stage medium-pressure compressor |

| Motor power(KW) |

Capacity (min/min) |

Exhaust pressure(bar) |

Motor revelution speed(rpm) |

Dimensions(L*W*H)mm |

Machine net weight(Kg) |

Noise(1 meter away) dB(A) |

Cooling method |

| 90 |

10 |

17 |

1480 |

2500*1600*1900 |

3000 |

80 |

Air cooling |

| 9.2 |

20 |

| 8.5 |

25 |

| 110 |

12.2 |

17 |

1480 |

2500*1600*1900 |

3200 |

82 |

Air cooling |

| 11 |

20 |

| 10 |

25 |

| 132 |

14.5 |

17 |

1480 |

2500*1600*1900 |

3400 |

84 |

Air cooling |

| 13.5 |

20 |

| 12.3 |

25 |

| 160 |

18 |

17 |

1480 |

2500*1700*2050 |

3600 |

86 |

Air cooling |

| 17 |

20 |

| 15 |

25 |

| 185 |

20.3 |

17 |

1480 |

2500*1700*2050 |

3800 |

88 |

Air cooling |

| 20.1 |

20 |

| 17.9 |

25 |

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| Parameters of 25-40bar series two stage medium-pressure compressor |

| Motor power(KW) |

Capacity (min/min) |

Exhaust pressure(bar) |

Motor revelution speed(rpm) |

Dimensions(L*W*H)mm |

Machine net weight(Kg) |

Noise(1 meter away) dB(A) |

Cooling method |

| 110 |

12.4 |

25 |

1480 |

3650*1950*2060 |

4500 |

80 |

Air cooling |

| 11 |

30 |

| 9.8 |

35 |

| 8.8 |

40 |

| 132 |

15 |

25 |

1480 |

3650*1950*2060 |

4600 |

82 |

Air cooling |

| 13.2 |

30 |

| 11.9 |

35 |

| 10.9 |

40 |

| 160 |

18.5 |

25 |

1480 |

4050*2250*2160 |

4900 |

84 |

Air cooling |

| 16.3 |

30 |

| 14.4 |

35 |

| 13.2 |

40 |

| 200 |

23 |

25 |

1480 |

4050*2250*2160 |

5100 |

86 |

Air cooling |

| 20 |

30 |

| 18 |

35 |

| 16.5 |

40 |

| 250 |

28 |

25 |

1480 |

4050*2250*2160 |

5300 |

88 |

Air cooling |

| 25 |

30 |

| 23.5 |

35 |

| 21 |

40 |

English

English  中文

中文  Español

Español  Русский

Русский

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)